Tesla Outsourcing Services LLC Enables US Construction's Off-Site Revolution with Fabrication-Ready BIM

The firm’s expertise in clash-free MEP modeling & shop drawings proves critical as contractors & developers embrace modular & prefabricated building methods

Prefabrication is not just a trend; it's a fundamental shift in construction. It demands absolute digital precision before the first component is ever built.”

NY, UNITED STATES, October 27, 2025 /EINPresswire.com/ -- Faced with persistent skilled labor shortages, rising material costs, and intense pressure for rapid project delivery, a growing number of developers and general contractors are embracing off-site construction. Tesla Outsourcing Services LLC, a global leader in digital engineering, has positioned itself as an essential partner in this revolution, providing the critical BIM (Building Information Modeling) services that form the digital backbone of this modern building method.— Ketan Poojara, CEO, Tesla Outsourcing Services LLC

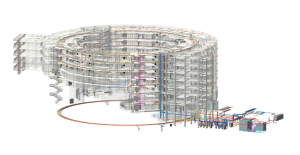

From modular multifamily housing and hotels to prefabricated bathroom pods and complex MEP racks for data centers, the "factory-built" model is moving from a niche concept to a mainstream solution. However, this shift introduces a new, high-stakes challenge: the complete intolerance for error.

𝐓𝐡𝐞 𝐍𝐞𝐰 𝐌𝐚𝐧𝐝𝐚𝐭𝐞: 𝐙𝐞𝐫𝐨-𝐓𝐨𝐥𝐞𝐫𝐚𝐧𝐜𝐞 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧

In traditional, on-site construction, minor discrepancies can often be resolved in the field with a grinder or a shim. In off-site manufacturing, there is no such margin for error. When a 10-ton prefabricated wall panel or a fully assembled bathroom pod is craned into place, it must fit its connections with millimeter accuracy. A clash or misalignment is not a minor inconvenience; it is a catastrophic failure that can halt an entire assembly line, invalidate thousands of dollars in fabricated materials, and derail a project's core promise of speed.

This industrial-grade approach demands a new level of digital planning. It requires a "digital twin" of a component that is so accurate it can be used for manufacturing. This is where Tesla Outsourcing Services LLC’s specialized expertise becomes indispensable.

"The core change is moving from 'BIM for Coordination' to 'BIM for Manufacturing'," explains Prex Poojara, V.P. of Tesla Outsourcing Services LLC. "The digital model is no longer just a map for on-site assembly; it is the assembly line. Our job is to create fabrication-ready models that provide absolute certainty, ensuring that what is built in the factory fits perfectly on the site, every single time."

𝐅𝐫𝐨𝐦 𝐃𝐢𝐠𝐢𝐭𝐚𝐥 𝐁𝐥𝐮𝐞𝐩𝐫𝐢𝐧𝐭 𝐭𝐨 𝐏𝐡𝐲𝐬𝐢𝐜𝐚𝐥 𝐂𝐨𝐦𝐩𝐨𝐧𝐞𝐧𝐭

The firm’s integrated workflow provides the end-to-end digital support required for a successful off-site strategy, seamlessly connecting the design phase to the factory floor.

✅ High-Fidelity Modeling: The process begins by modeling the core architectural and structural components: the walls, floors, and ceilings—to exact manufacturing specifications. This includes precise locations for all structural connections, openings, and service penetrations.

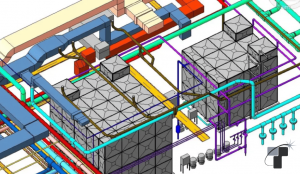

✅ MEP Coordination: The greatest challenge in modular construction is fitting complex MEP (Mechanical, Electrical, and Plumbing) systems into highly confined spaces. The specialists perform rigorous, multi-disciplinary coordination to route dense ductwork, piping, and conduit within the modules, resolving thousands of potential hard and soft clashes digitally. This ensures systems are not only clash-free but are also accessible for future maintenance.

✅ Fabrication-Ready Shop Drawings: This is the most critical deliverable. The fully coordinated, clash-free BIM model serves as the single source of truth from which manufacturing-level MEP shop drawings are extracted. These drawings are not mere guides; they are the precise, data-rich instructions the factory floor uses to fabricate and assemble components. This seamless digital-to-fabrication pipeline eliminates ambiguity and ensures the final product is a perfect 1:1 match of the approved design.

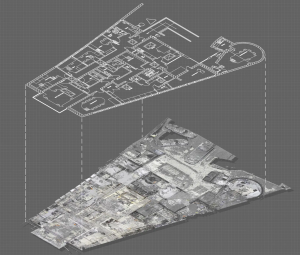

This capability is especially critical for contractors leveraging Scan to BIM for existing buildings, where prefabricated components must integrate with as-built conditions. The company’s expertise in converting point cloud data into an accurate BIM model provides the reliable foundation needed to design and manufacture off-site elements with confidence.

𝐀 𝐆𝐥𝐨𝐛𝐚𝐥 𝐃𝐞𝐥𝐢𝐯𝐞𝐫𝐲 𝐌𝐨𝐝𝐞𝐥 𝐟𝐨𝐫 𝐚𝐧 𝐀𝐜𝐜𝐞𝐥𝐞𝐫𝐚𝐭𝐞𝐝 𝐌𝐚𝐫𝐤𝐞𝐭

The primary driver for off-site construction is speed. To support these compressed timelines, Tesla Outsourcing Services LLC leverages its strategic operational structure, paired with a large-scale, 200+ specialist drafting and production center in India.

Project teams in the US can send design revisions or coordination requests at the end of their workday and receive updated models and drawings the next morning.

"In a modular project, speed is everything, but it cannot come at the cost of accuracy," adds Bhagwati Pathak, COO. "Our scalable operational capacity means we can run complex clash-detection analyses and produce detailed shop drawings overnight, not over a week. We provide a scalable, expert workforce that integrates seamlessly with our clients' teams, allowing them to meet aggressive deadlines without sacrificing the precision that fabrication demands."

As the US construction industry continues to industrialize, the role of expert digital engineering partners has become non-negotiable. By providing the digital certainty required for a zero-tolerance manufacturing process, Tesla Outsourcing Services LLC is proving to be a critical enabler of this faster, more efficient, and more sustainable method of building.

𝐀𝐛𝐨𝐮𝐭 𝐓𝐞𝐬𝐥𝐚 𝐎𝐮𝐭𝐬𝐨𝐮𝐫𝐜𝐢𝐧𝐠 𝐒𝐞𝐫𝐯𝐢𝐜𝐞𝐬 𝐋𝐋𝐂

Tesla Outsourcing Services LLC is a premier provider of digital engineering solutions for the global Architecture, Engineering, and Construction (AEC) sector. As a testament of BIM grandeur, the company has built a legacy of precision and reliability since 2007, with its team of 200+ dedicated BIM specialists completing over 5,000 projects across more than 25 countries. The firm is a recognized leader in providing fabrication-ready digital models for off-site construction, specializing in complex MEP coordination and shop drawings. With a commitment to international standards like ISO 19650, Tesla is dedicated to delivering the digital precision that powers modern manufacturing and construction.

Divya Dave

Tesla Outsourcing Services LLC

+1 416-907-9430

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.